South Korea’s Samsung Biologics Co., the world’s largest contract drugmaker, on Wednesday posted its largest-ever annual sales and operating profit, driven by a steady stream of profitable drug-making contracts for pharmaceutical firms.

The biotechnology unit of Korea’s top conglomerate Samsung Group said in a regulatory filing that it posted 1.32 trillion won ($919 million) in operating profit last year on a consolidated basis, up 18.5% from 1.11 trillion won the previous year.

Its net profit rose 26.3% to 1.08 trillion won.

Its consolidated 2024 sales were 4.55 trillion won, up 23% from 3.69 trillion won.

With its 2024 revenue, Samsung became the first Korean biopharmaceutical firm with annual sales surpassing 4 trillion won.

In the fourth quarter of 2024, its net profit rose 10.6% on-year to 321.5 billion won, while its operating profit fell 6.9% to 325.7 billion won. Quarterly sales gained 17% to 1.26 trillion won.

In the regulatory filing, the company said it aims to achieve 2025 sales revenue of 5.57 trillion won.

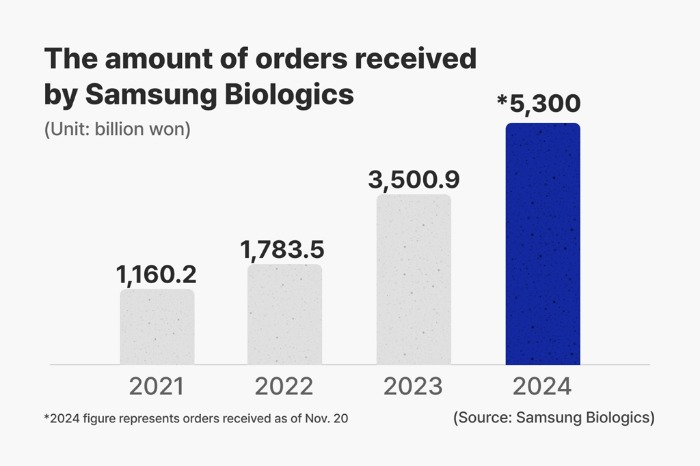

CUMULATIVE ORDERS AT ALL-TIME HIGH

The company’s contract value for 2024 stood at 5.4 trillion won, a record annual high. That compares with 3.5 trillion won worth of orders in 2023.

Since its foundation in 2011, its cumulative orders have exceeded 25 trillion won.

Samsung Biologics said it has partnered with 17 of the world’s top 20 pharmaceutical companies to make medicines for them under contracts in the antibody drug segment, including cancer treatment, autoimmune disease therapies and biosimilars.

Samsung said it virtually has contracts with all major pharmaceutical companies since the remaining three firms are biosimilar makers, meaning partnerships with them create a conflict of interest.

The company has focused on manufacturing drugs for others in a scheme known as a contract manufacturing organization (CMO) for over a decade.

Last week, Samsung signed a $1.4 billion CMO deal – its single largest contract – with an unidentified European biopharmaceutical firm.

It now aims to solidify its leadership in the contract development and manufacturing organization (CDMO) market, which involves cooperation from the more profitable drug development stage.

Samsung has been ramping up its facilities to meet growing client demand.

Most biopharmaceutical companies such as Pfizer, Moderna, AstraZeneca, and Janssen, Johnson & Johnson’s pharmaceutical division, focus only on R&D. Without their own production facilities, they outsource production to contract drugmakers.

In terms of capacity, Samsung Biologics is already the world’s largest contract manufacturer, followed by Swiss rival Lonza AG and Germany’s Boehringer Ingelheim.

Samsung broke ground on its 5th plant with a production capacity of 180,000 liters in April 2024 and is slated to be completed by this April, further cementing its leadership as the top CDMO player.

Once the latest factory comes online, Samsung will have a total capacity of 784,000 liters.

FOCUS ON ADC BUSINESS

Samsung is now focusing on antibody-drug conjugates (ADCs), a promising area in oncology.

Last December, the company completed a dedicated ADC production plant in Songdo, Incheon – a four-story building with a 500-liter conjugation reactor and one purification line.

ADC therapy has emerged as a promising cancer treatment despite its high technological barriers. Once they are successfully developed, ADC drugs have shown excellent clinical efficacy against various cancers such as breast cancer and gastric cancer as well as urothelial carcinoma.

ADCs are called biological missiles, consisting of antibodies, payloads and linkers. The antibody guides the payload, or small molecule drugs that act as a warhead, and the linker connects the antibody and the payload.

The global ADC therapy market is forecast to expand from $7.7 billion in 2023 to $38.7 billion by 2029 at an average annual growth rate of 23.7%, according to global bio data compiled by the Korea Drug Development Fund.

Earlier this month, Samsung signed an initial agreement with LigaChem Biosciences Inc., a Korean biotech startup, to jointly develop and produce ADC products.

By In-Soo Nam

isnam@hankyung.com

Jennifer Nicholson-Breen edited this article.