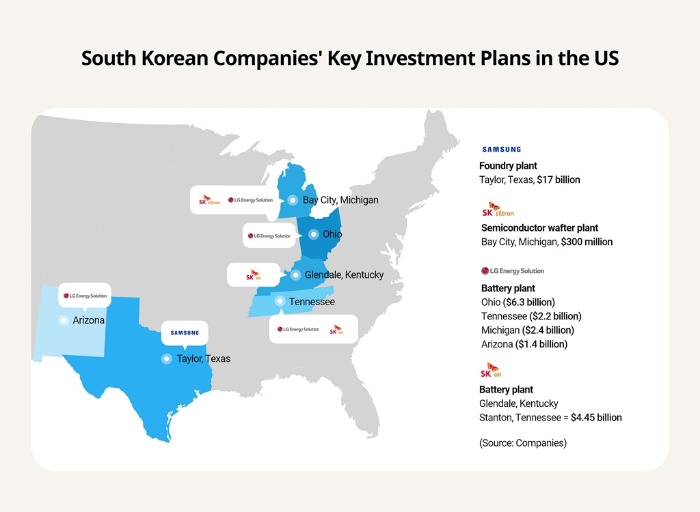

South Korea’s SK Siltron Co. has secured a $544 million loan from the US Department of Energy (DOE) to invest in a high-quality silicon carbide (SiC) wafer manufacturing facility in Bay City, Michigan.

Industry sources said on Wednesday that SK’s US affiliate SK Siltron CSS LLC last week signed a formal contract to win the loan under the Advanced Technology Vehicles Manufacturing Loan Program (ATVM).

The DOE, which gave conditional approval in February, has also made the loan official through its Loan Program Office (LPO) blog.

The loan – $481.5 million of principal and $62.5 million of capitalized interest – is part of the Biden administration’s “Investing in America” agenda that supports the onshoring and re-shoring of domestic manufacturing technologies critical to meeting the US government’s goal that half of all new vehicles sold in 2030 are zero-emissions vehicles.

SK Siltron plans to use the loan to expand SiC wafer production facility in Bay City. The Korean company aims to begin mass production of the material in 2025 at its plant in Gumi, Korea and the expanded facility in Bay City.

HIGHLY VALUABLE PRODUCT

SK Siltron CSS manufactures SiC wafers, a semiconductor material ideal for wide-ranging applications due to its high thermal resistance and high level of hardness.

SiC semiconductors are designed for high-power and high-voltage applications, where efficiency and reliability are highly valuable. They are critical components of EV drivetrains, including inverters, and electrical distribution systems like onboard chargers and DC-to-DC converters.

SiC wafers have significant advantages over silicon wafers, such as withstanding 10 times higher voltage and three times higher temperatures, making them crucial for power semiconductors used in electric vehicles and renewable energy generation.

SiC semiconductors enhance the charging speed of EVs by 75%, increase mileage by 7.5% and reduce inverter module weight and volume by over 40% compared with traditional silicon semiconductors.

Due to the high technological barriers of SiC wafer production, only a handful of companies have the design and manufacturing capabilities.

Major SiC wafer makers include SK Siltron, Japan’s Shin-Etsu Chemical Co. and Sumco Corp., Taiwan’s GlobalWafers Co. and Germany’s Siltronic AG.

In 2023, SK Siltron CSS clinched a long-term supply contract with Germany’s Infineon Technologies AG, a leading SiC power semiconductor maker.

SK Siltron controls 6% of the global SiC wafer market as of 2023.

According to market research firm Yole Group, the SiC device market is forecast to grow to $990 million by 2029 from $270 million in 2023, driven by the growth of the EV market, expanded charging infrastructure and increased renewable energy generation like solar and wind.

SK CHAIR CHEY TAE-WON WELCOMES THE DOE MOVE

SK Siltron, 51% owned by the parent group’s holding company SK Inc., bought the Bay City, Auburn plant from US industrial materials maker DuPont for $450 million in 2020.

The Korean company has invested $630 million over six years to build new SiC wafer facilities in Bay City and expand its Gumi plant.

Production of next-generation 200-millimeter SiC wafers is expected to begin in 2025.

SK Group Chairman Chey Tae-won has been leading business cooperation between the US and Korea.

SK has invested $30 billion in US companies in future-oriented industries such as semiconductors, renewable energy and life sciences since 2019.

Chey was part of Korea’s economic delegation to the US in April 2023 when Korean President Yoon Suk Yeol visited Washington to have a summit meeting with Biden.

“SK Siltron CSS is the proof of a successful US-Korea partnership,” said the SK chairman.

With the US loan to SK Siltron finalized, industry officials are now looking to see how much Samsung Electronics Co. can receive from the US government in chip subsidies.

The US government is reportedly working to finalize subsidy agreements with Samsung, Intel Corp., Micron Technology Inc. and others.

By Jeong-Soo Hwang

hjs@hankyung.com

In-Soo Nam edited this article.